Intertech is a leading supplier for Electronic mold, making all kinds of electronics mold and electronics item mold, home electronics mold in Taiwan. Intertech's services include prototyping, tooling, lab testing, production and assembly.

Our customer's concept of products will be brought out from design to the discussion to its completion through our designers and engineers.

Consumer electronic mold service:

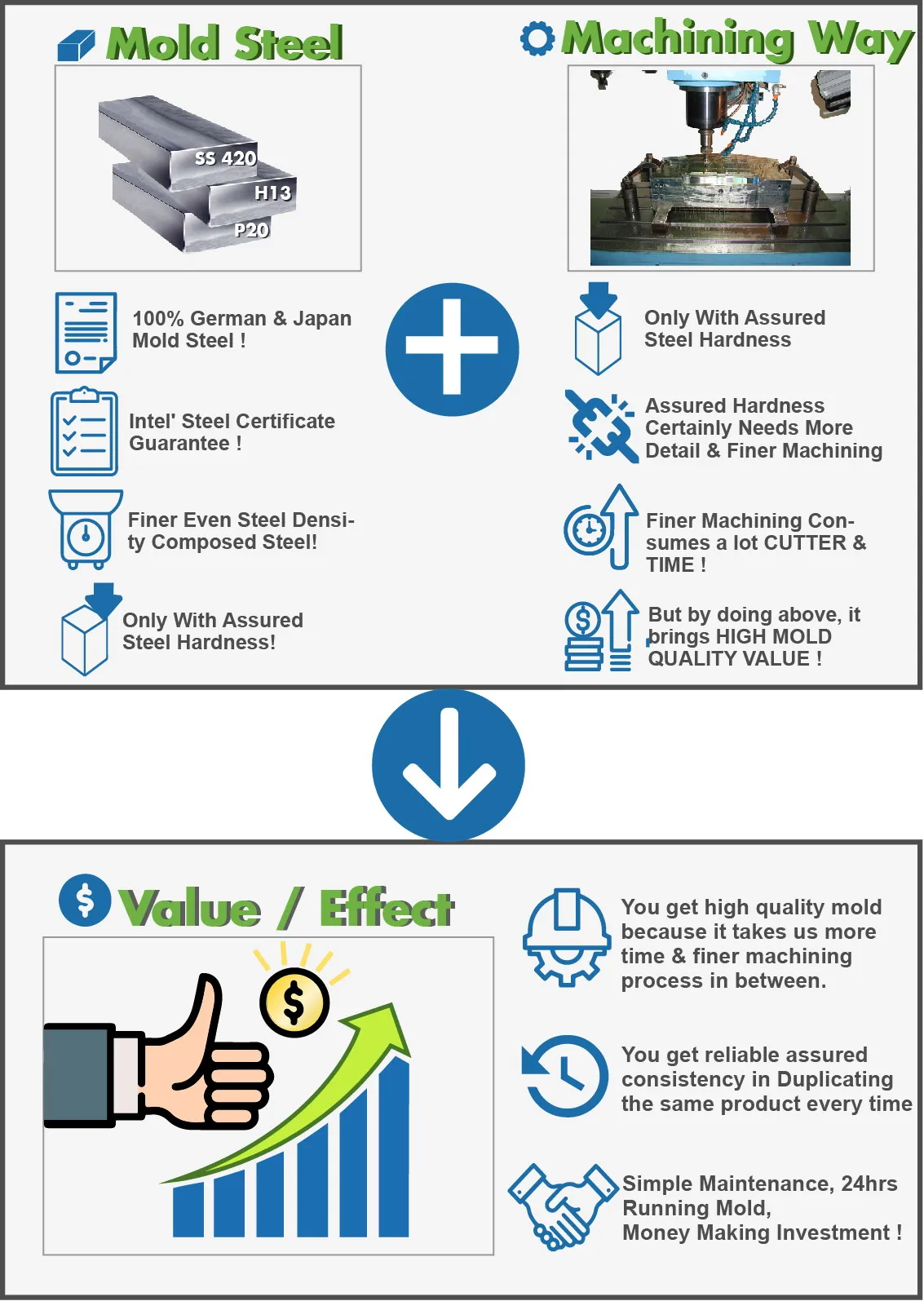

Intertech Machinery ,our engineer have professional plastic components experiences in using electronic devices and system assemblies. Intertech Machinery not only promise the quality of electronic mold service but also mold safety is paramount when it comes to human environment in our moulding company .

As electronic devices get smaller and more sophisticated, the need for accuracy and consistency of the component parts becomes more necessary. We manufacture precision, complex geometries for electronic mold service mold such as item for light pipes, switches, battery packs, contact blocks, as well as a range of products from single function devices to high-end electronic equipment.

Intertech is a company specialized in mold in plastic moulding manufacturer. Our products are widely applied to mold in plastic moulding manufacturer.

All of the products made by Intertech are of high quality but priced reasonably.

Intertech makes good quality new custom mold and molded parts for any plastic, silicone and metal project, please send us your project now !

Sample order is available after our discussion !

We can give you some suggestion for our best selling mold and molding parts project working way !

May we have your Whatsapp number ? we can talk there more quickly or you

can add ours Whatsapp: +886.9328.66329

Intertech Machinery is good at manufacturing plastic mold components used in industrial and packaging applications. Per customer’s demand, we will discuss the raw material required, the color master batch requires, mold making size required, molding machine size required, cycle time estimation, production time calculation report…etc with customers. After that, parts design service, mold engineering service, mass production arrangement, post assembly service or post machining service are also provided.

Each mold and molding projects case, we will see client specifications to serve the needs of a wide variety of industries. Our injection mold technology have D&B D-U-N-S compliant working system and meets high industry standards. We can mold any plastic, metal and rubber projects for customers. We have advanced machinery equipment to provide small to larger mold projects and also manufacture thermoplastic, engineering plastics, silicone rubber and metal parts.

Are you from the EU regions?

Taiwantrade.com and iDealEZ.com uses analytical cookies and other tracking technologies to offer you the best possible user experience. By using our website, you acknowledge and agree to our cookie policy.

For more information on cookies or changing your cookies settings, read Taiwantrade & iDealEZ’s Privacy Policy.