injection mould

Intertech is based 100% in Taiwan with more than 30 years experience. We help customer to make customized plastic injection molds, particularly in the material of high quality steel purely imports from German and Japan. We commonly use mold steel such as P20 (1.2311), H13 (1.2344) and Starvax 420 (stainless steel), and with simple maintenance, all these tools can run min. 200000 ~ 1000000 shots under ideal operational condition.

Taiwan Mold and Molding Factory

Over 30 years experience, Intertech offers customers with intelligent and cost saving mold and molding solutions to their production need in Taiwan.

We can make the quality molds for your most complex parts and projects, including mold manufacturing, assembly, testing, and packaging.

With 30 years experience, we manage very well in contract manufacturing, including the material selection, customer design checking, engineering discussion, tooling, pilot run, mass production, post operations, quality control and supply chain management.

We have excellent mold making lead time, some molds 40 days, some molds even 35 days, up to your parts design.

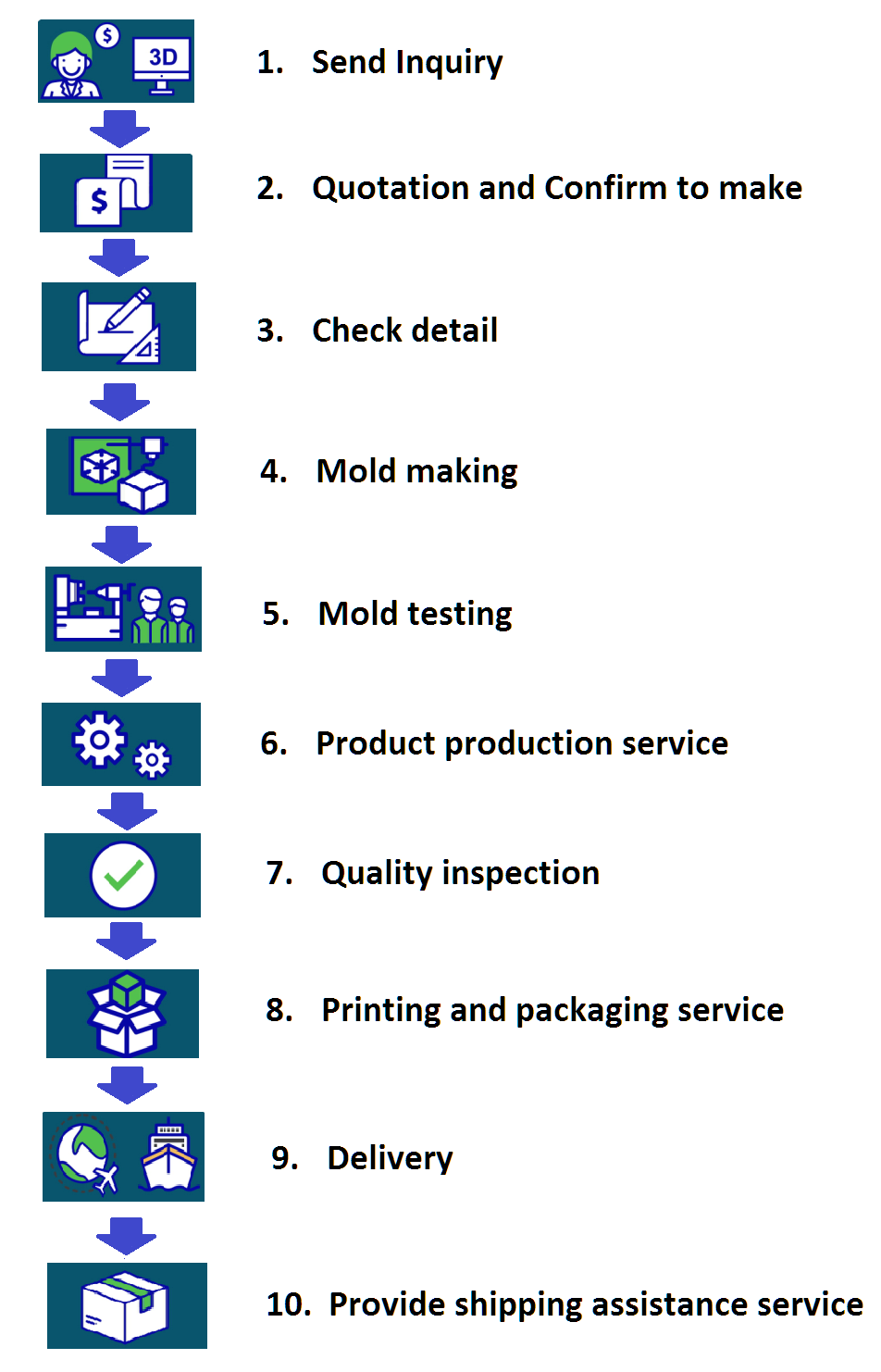

Custom Service

- 1.Send Inquiry

- 2.Quotation and Confirm to make

- 3.Check detail

- 4.Mold making

- 5.Mold testing

- 6.Product production service

- 7.Quality inspection

- 8.Printing and packaging service

- 9.Delivery

- 10.Provide shipping assistance service

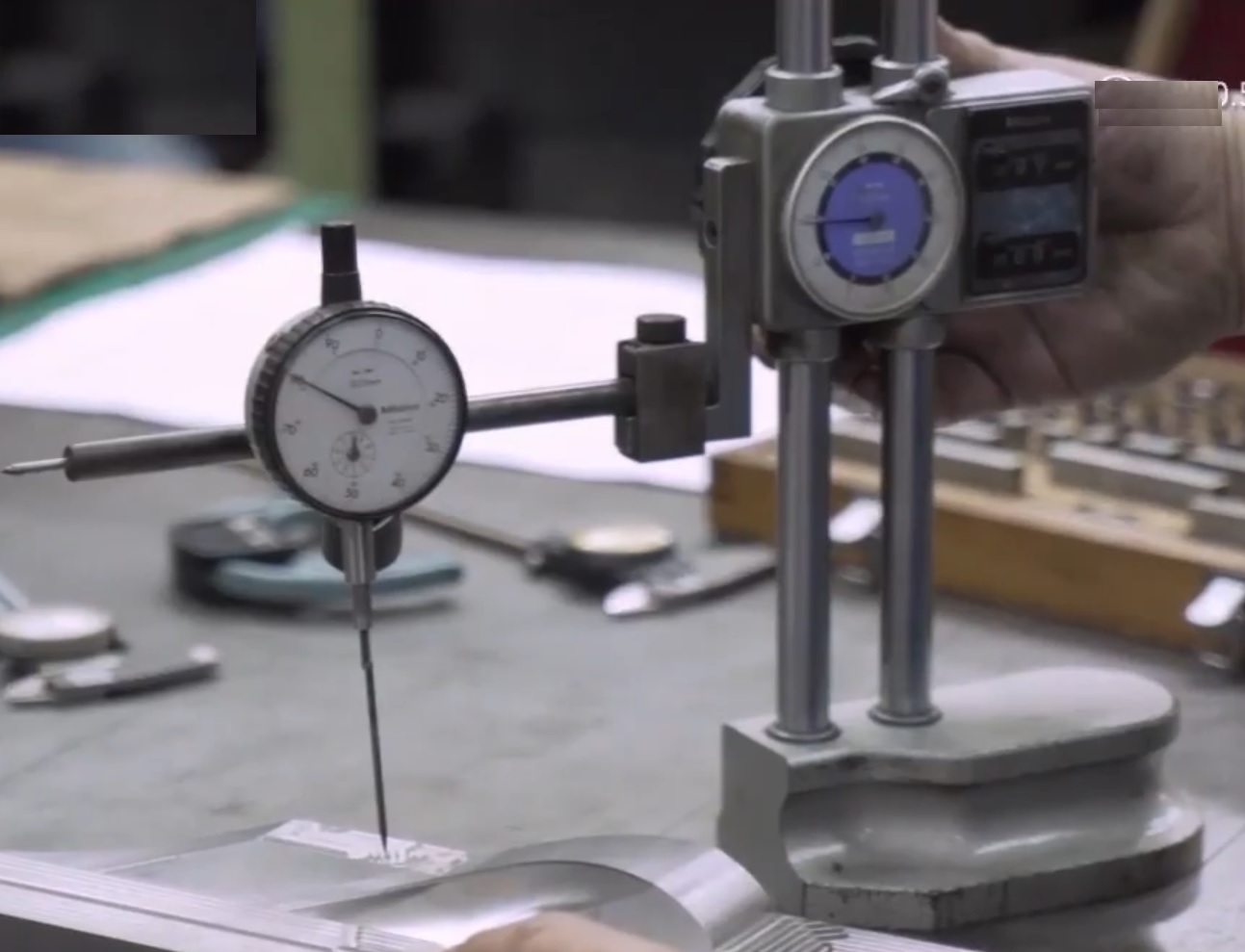

Mold making process

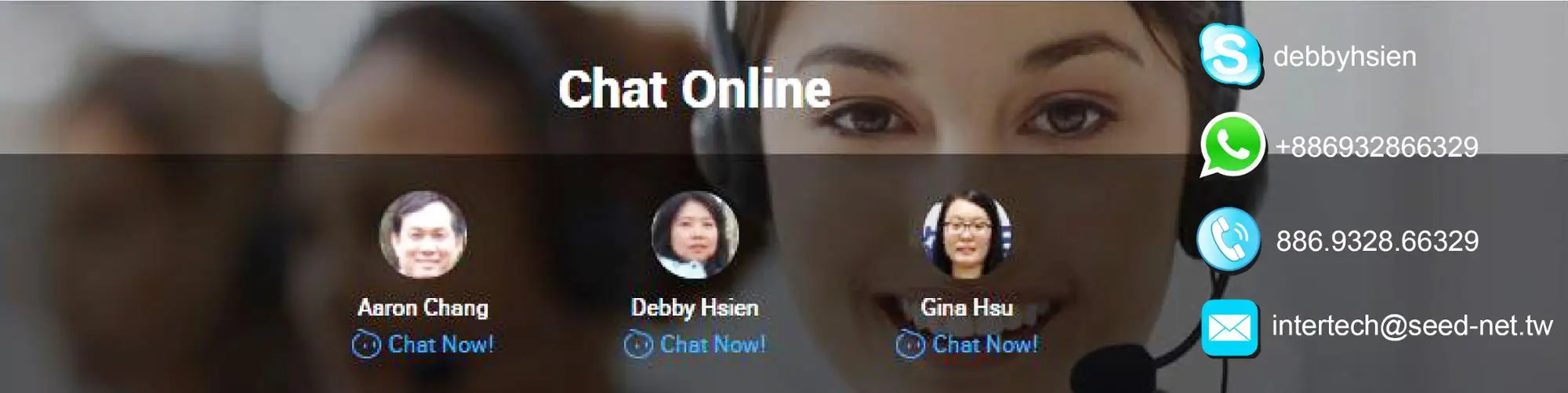

Contact us

Intertech makes good quality new custom mold and molded parts for any plastic, silicone and metal project, please send us your project now !

Sample order is available after our discussion !

We can give you some suggestion for our best selling mold and molding parts project working way !

May we have your Whatsapp number ? we can talk there more quickly or you

can add ours Whatsapp: +886.9328.66329

.jpg)