Plastic Materials Development Tooling Service

Step 1: Project Discussion

•Product development by testing

•Parts requirement details

Step 2: Prototype Tool Making

•Testing with different materials

Step 3: Prototype Tool Making

Step 4: Prototype Tool Testing

•Sample measuring

•Sample sending

Step 5: Future tooling

•Future tooling development possibility report

Intertech is an expert in

molding design, plastic mold design,injection mold design engineering,3D mold design, mold engineering services,

prototype tooling service.

We do offer prototype tool making tests for process development engineers. After discussion, we can test different materials for you, measuring the samples, and send them to you.

We mainly use Pro-E, Solidworks software for 3D (.igs or .stp format) AutoCad for 2D (.dwg) Up to customer’s requirement, we provide the

custom mold flow analysis service. Before making the mold flow analysis design, through the mold flow analysis, customer can optimize their parts design by checking the material filling, deformation, shrinkage, welding line, temperature, shear stress, hot runner layout…etc to de-bug the parts design mistake, to simplify the

manufacturing process and to raise up the positive productivity rate.

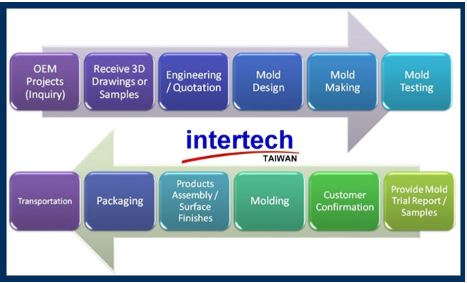

Here is how we do it.

Pre-Schedule :

Pre-Schedule :- Customer inquiry (with sending parts 2D, 3D, photo, sample)

- Engineering analysis (CAD/CAM), parts structural checking

- Receipt of order from customer

Production-Schedule :

- Mold design (mold drawing, components drawing, CAD/CAM)

- Getting mold design approval from customer.

- Preparing for manufacture (direct numeric control, CAD/CAM, ordering

of tool steel & components, outside processes with subcontractors)

- Machining

- Finishing machining

- Mold trial

- Assembly & inspection (part measurement, feature Test, etc.)

- Packing and shipping to customer

Payment Details

- Payment Terms:TT ,L/C

- Minimum Order:1 Set/ Sets

About us

Intertech is a professional molding design, plastic mould design,molding design, molding design,injection mold design engineering,3D mold design,mould engineering services supplier. Find more mold design, molding design, plastic mould design,mould engineering services information here or contact us for full service.

Intertch provides mold design for customers. We mainly use Pro-E, Solidworks software for 3D (.igs or .stp format) AutoCad for 2D (.dwg)

Up to customer’s requirement, we provide the custom mold flow analysis service. Before making the mold flow analysis design, through the mold flow analysis, customer can optimize their parts design by checking the material filling, deformation, shrinkage, welding line, temperature, shear stress, hot runner layout…etc to de-bug the parts design mistake, to simplify the manufacturing process and to raise up the positive productivity rate.