Promotional high quality OEM hot sale plastic container mould

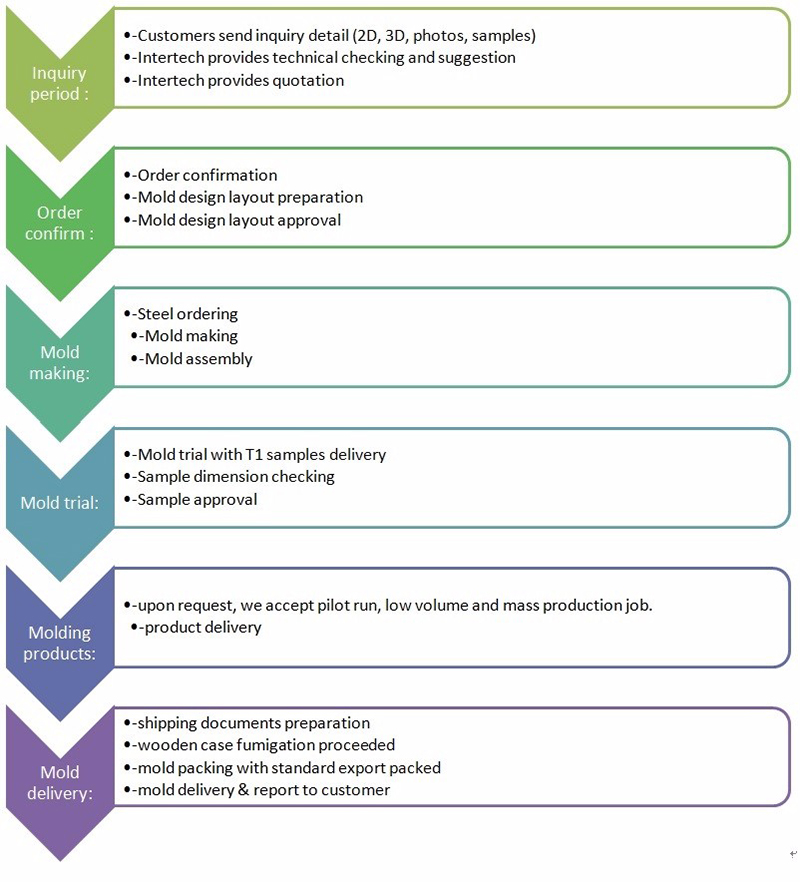

Intertech is a leading supplier for Plastic container mold, making all kinds of custom plastic containers and plastic storage boxes mold and plastic container mould in Taiwan. Intertech's services include prototyping, tooling, lab testing, production and assembly

20 Liter Plastic Round Container Mold

Intertech is a leading supplier for Plastic container mold, making all kinds of custom plastic containers and plastic storage boxes mold in Taiwan. Intertech's services include prototyping, tooling, lab testing, production and assembly

Intertech had made many good different sizes of plastic container molds and plastic lids molds for many customers. We had made 4.5 liter container and lid molds (both for round and square shapes), 13.5 liter container and lid molds (both for round and square shapes), 20 liter container and lid molds (both for round and square shapes), handle molds and knob molds…etc.

Welcome to send us your new mold project !

Intertech Machinery is good at manufacturing plastic mold components used in industrial and packaging applications. Per customer’s demand, we will discuss the raw material required, the color master batch requires, mold making size required, molding machine size required, cycle time estimation, production time calculation report…etc with customers. After that, parts design service, mold engineeringservice, mass production arrangement, post assembly service or post machiningservice are also provided.

Each mold and molding projects case, we will see client specifications to serve the needs of a wide variety of industries. Our injection mold technology have D&B D-U-N-S compliant working system and meets high industry standards. We can mold any plastic, metal and rubber projects for customers. We have advanced machinery equipment to provide small to larger mold projects and also manufacture thermoplastic, engineering plastics, silicone rubber and metal parts.

We provide low volume, pilot run of production job and mass production for customer.

| Product Name | mold |

| Plastic Material | PP , PE , ABS , POM , PET, PBT, Nylon + GF…..etc. |

| Steel of Cavity & Core | Up to customer’s budget and productivity required, |

| Steel of Mold Base | Up to customer’s budget and requirement , we suggest different mold base steel to clients. Normal used material S50C, or P20 |

| No. of Cavity | Customized |

| Hardness of Cavity & Core | Pre-Hardenss Steel : HRC 30~32+-1* |

| Core pulling or Ejection system | Depends on the Products. |

| Mould Accessories | Compatible to DME/ HASCO Standard. |

| Cooling System | In Core : Baffle or By pass cooling |

| Surface Finish | Up to the prodct’s requirement, Normal used : Texture, EDM maching , Polishing |

| Mold Life | Up to mold steel grade, under ideal operation condition, |

| Runner | 1. Cold runner |

| Delivery time | 40~50 days , presenting T1 samples |

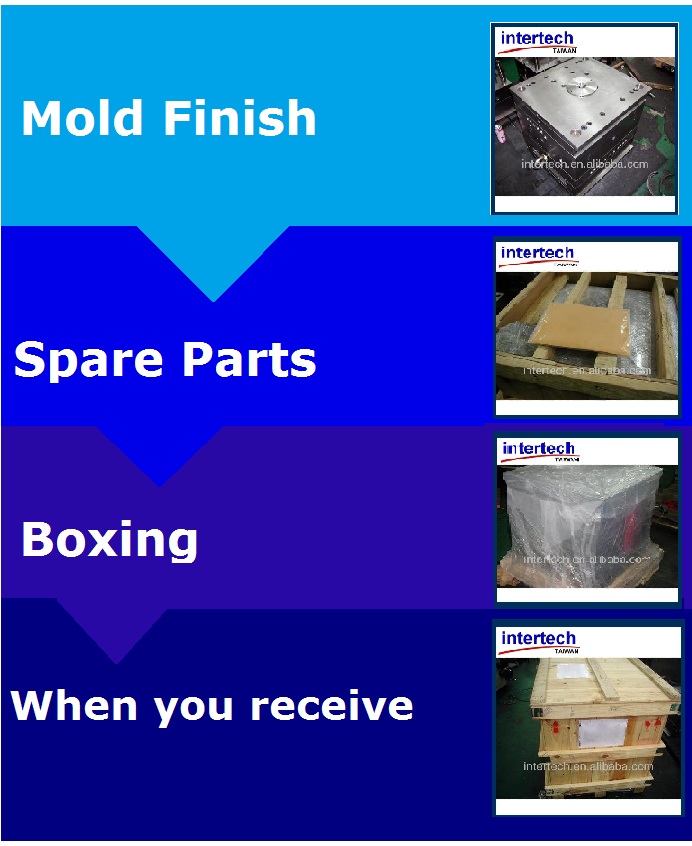

| Packing | Standard Wooden Case |

| Production | We can also provide Pilot Run production and molding production |

Are you from the EU regions?

Taiwantrade.com and iDealEZ.com uses analytical cookies and other tracking technologies to offer you the best possible user experience. By using our website, you acknowledge and agree to our cookie policy.

For more information on cookies or changing your cookies settings, read Taiwantrade & iDealEZ’s Privacy Policy.