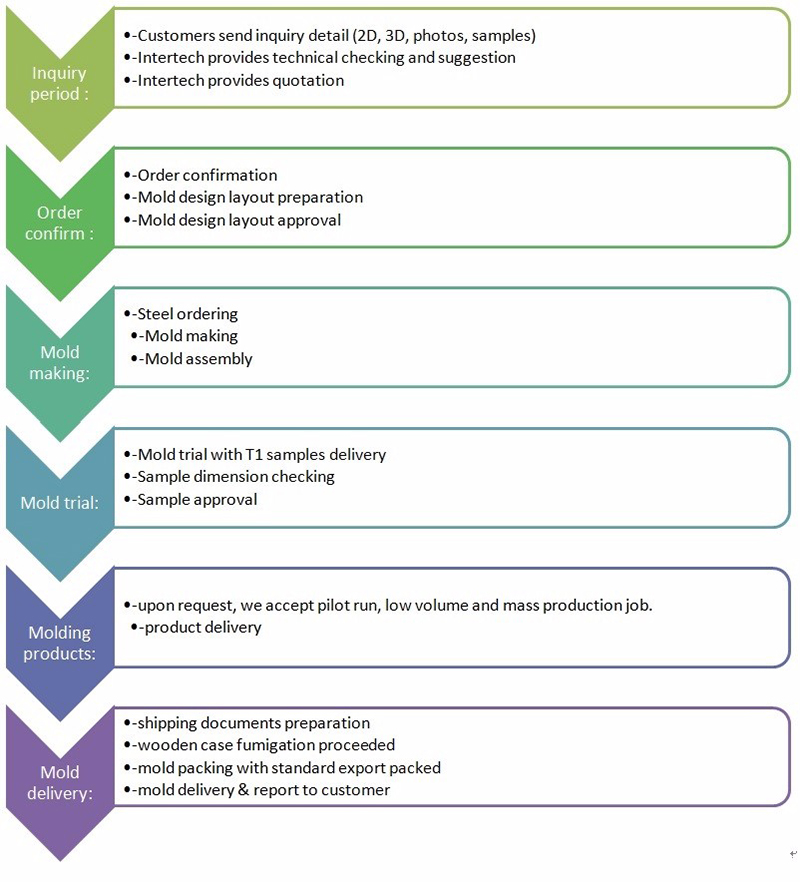

Intertech makes good injection mold for packaging items, such as cosmetic box mold, plastic bucket mold, plastic box mold & plastic container mold detail.

Intertech is a leading supplier for Plastic container mold, making all kinds of custom plastic containers and plastic storage boxes mold in Taiwan. Intertech's services include prototyping, tooling, lab testing, production and assembly

Intertech had made many good different sizes of plastic container molds and plastic lids molds for many customers. We had made 4.5 liter container and lid molds (both for round and square shapes), 13.5 liter container and lid molds (both for round and square shapes), 20 liter container and lid molds (both for round and square shapes), handle molds and knob molds…etc.

Welcome to send us your new mold project !

Taiwantrade.com and iDealEZ.com uses analytical cookies and other tracking technologies to offer you the best possible user experience. By using our website, you acknowledge and agree to our cookie policy.

For more information on cookies or changing your cookies settings, read Taiwantrade & iDealEZ’s Privacy Policy.