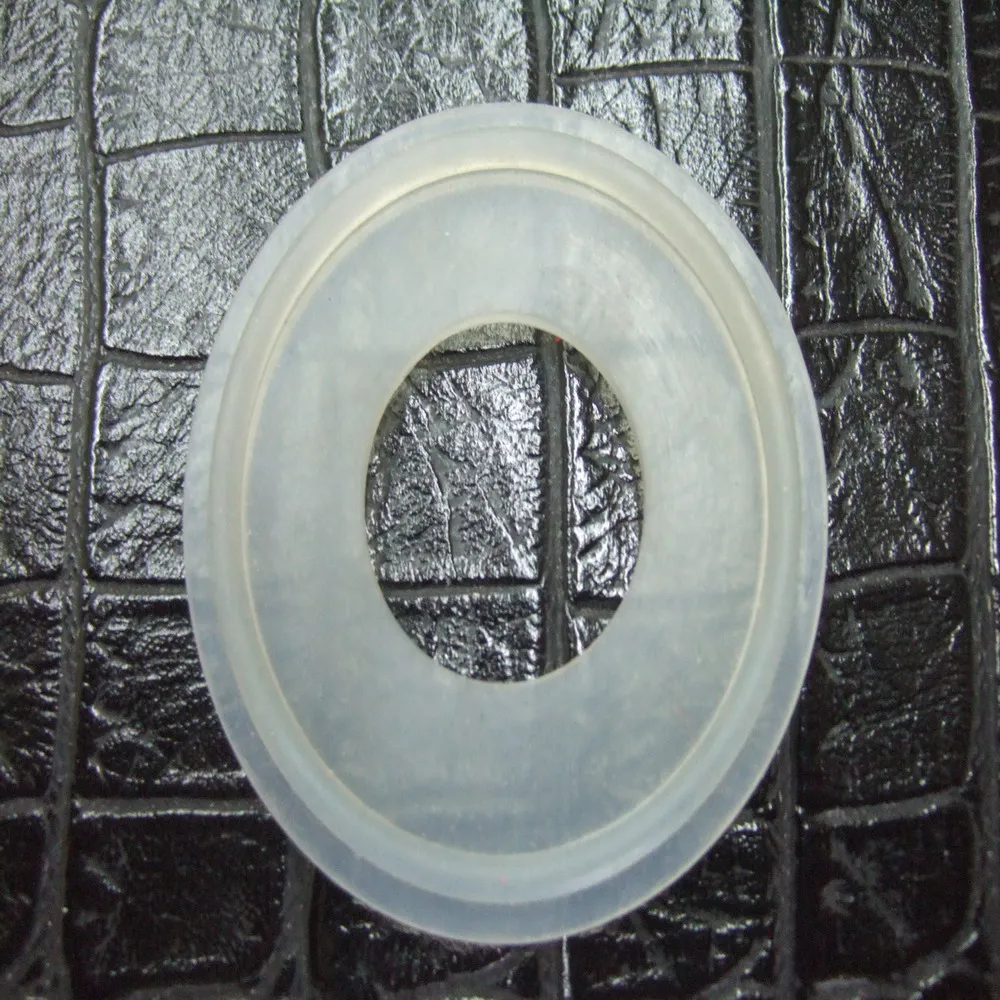

Silicone Rubber Diaphragm Rubber Seal Parts

Intertech is a professional Silicone Rubber Diaphragm Rubber Seal Parts mold, duckbill valve mold & unbrealla check valves mold ,Silicone Rubber Diaphragm Valve mold services Supplier. Find more silicone air diaphragm valve mold, Silicone Rubber Diaphragm Air Check Valve & umbrella check valves mold service information here or contact us for full service.

This silicone valve we do the silicone moulding can contact with liquid and with anti-corrosives… oxidizers… alkali or acid features.

Silicone valve material we use are quailed for fitting REACH standard.

Valve outlet hole cutting is done outside with fixture and tools in our mould company.

More Applications:

-in Aerospace (silicone molded seals…)

-in Medical and health care (silicone molded membranes, seals…)

-in Electronic (connection insulators…)

-in Cooking / Baking (silicone molded spatulas…)

-in Agricultural (seals…)

Liquid Silicone Rubber (LSR) parts mold and molding application examples :

Available to produce extensive coloring or high transparency option in the finished molded LSR products.

Capable in managing medical grade, food grade, normal grade liquid . Silicone molded products projects.

Our mold development for liquid silicone has a wide range of product application lines as such : baby nipple, pacifiers, seals, membrances, smooth surface LSR parts, respirator, medical mask, check valve, mouth guard, tension ring, diving masks…etc.

Plastic materials: | PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PBT+GF30%...etc. |

Other materials: | Rubber, Silicone rubber, LSR, aluminum, zinc...Metal...etc. |

Quality: | ROSH and SGS standard |

Feature: | Non marking and Non flash |

Size: | According to your drawing |

Color, Quantity, Unit price, Tooling cost, Tooling size: | To be discussed |

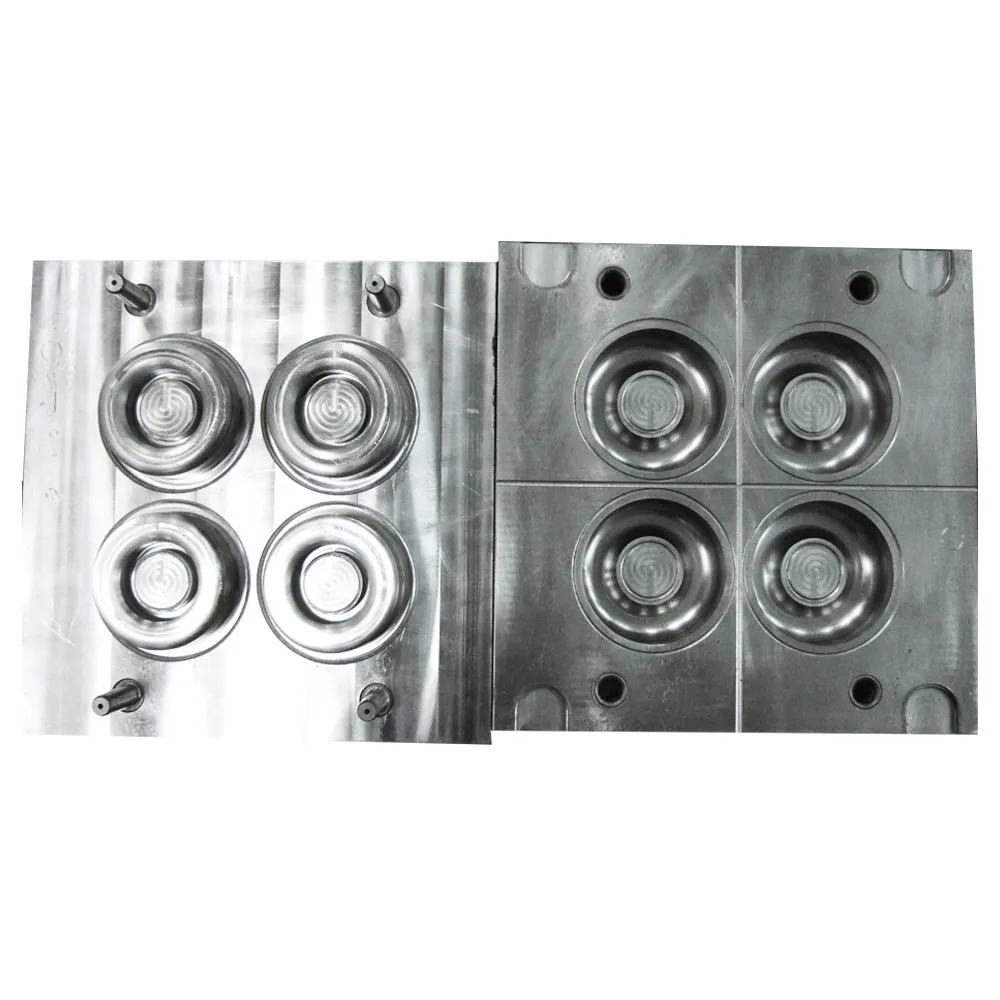

Mold structure: | Injection Mould, Plastic Mold, Overmould, 2k mould, Die-Casting Mould, Thermoset Mold, Stack Mold, Interchangeable Mold, Collapsible Core Mold, Die Sets, Compression Mold, Cold runner system LSR Mold,…etc. |

Mould Base: | HASCO standard, European standard, World standard |

Mould Base Material: | LKM, FUTA, HASCO, DME, etc. or as per customer’s requirement. |

Surface Finish: | Texture (MT standard), high gloss polishing |

Finish: | Mirror finish etc. |

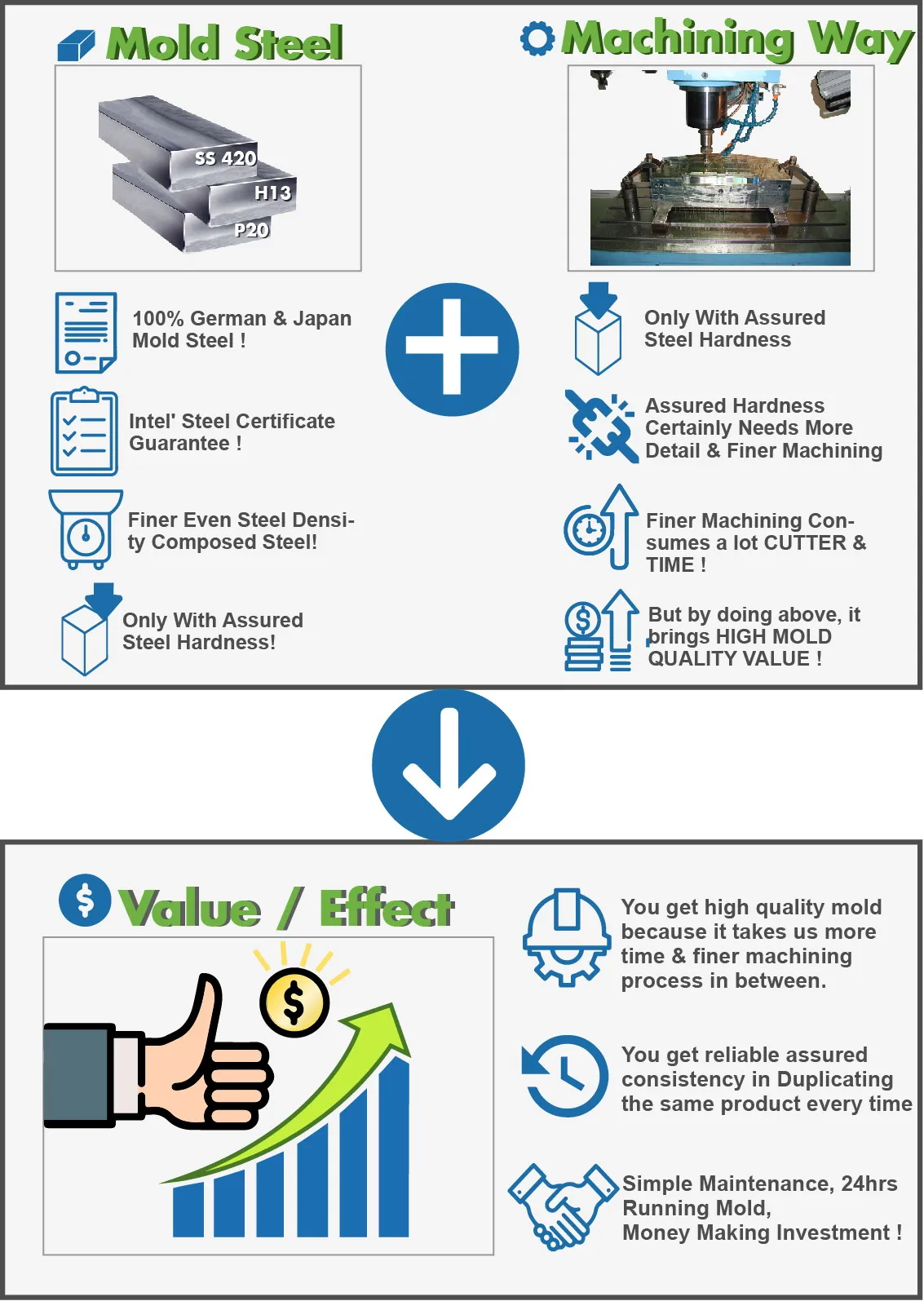

Cavity / Core steel: | P20, 2311, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 etc. |

Cavity: | Single cavity, Muti Cavity, based on customer’s requirement. |

Hot / Cold Runner: | HUSKY, INCOE, YUDO, HASCO, DME, MoldMaster, Masterflow, Mastip, Taiwan made brand…etc. |

Mould Life: | 1,000 to 1,000,000 shots (according to your working environment) |

Design & Program Softwares: | CAD, CAM, CAE, Pro-E, Solid works…etc. |

Equipments: | High speed CNC, standard CNC, EDM, Wire Cutting, Grinder, Plastic Injection Molding Machine for testing mold from 50-3000T available. |

Package: | Standard exported wooden box packed, fumigation process (upon required) |

Mold building lead time: | T1, 40~50 days, parts measurement report (upon required). |

Annual production: | 250 sets of mold |

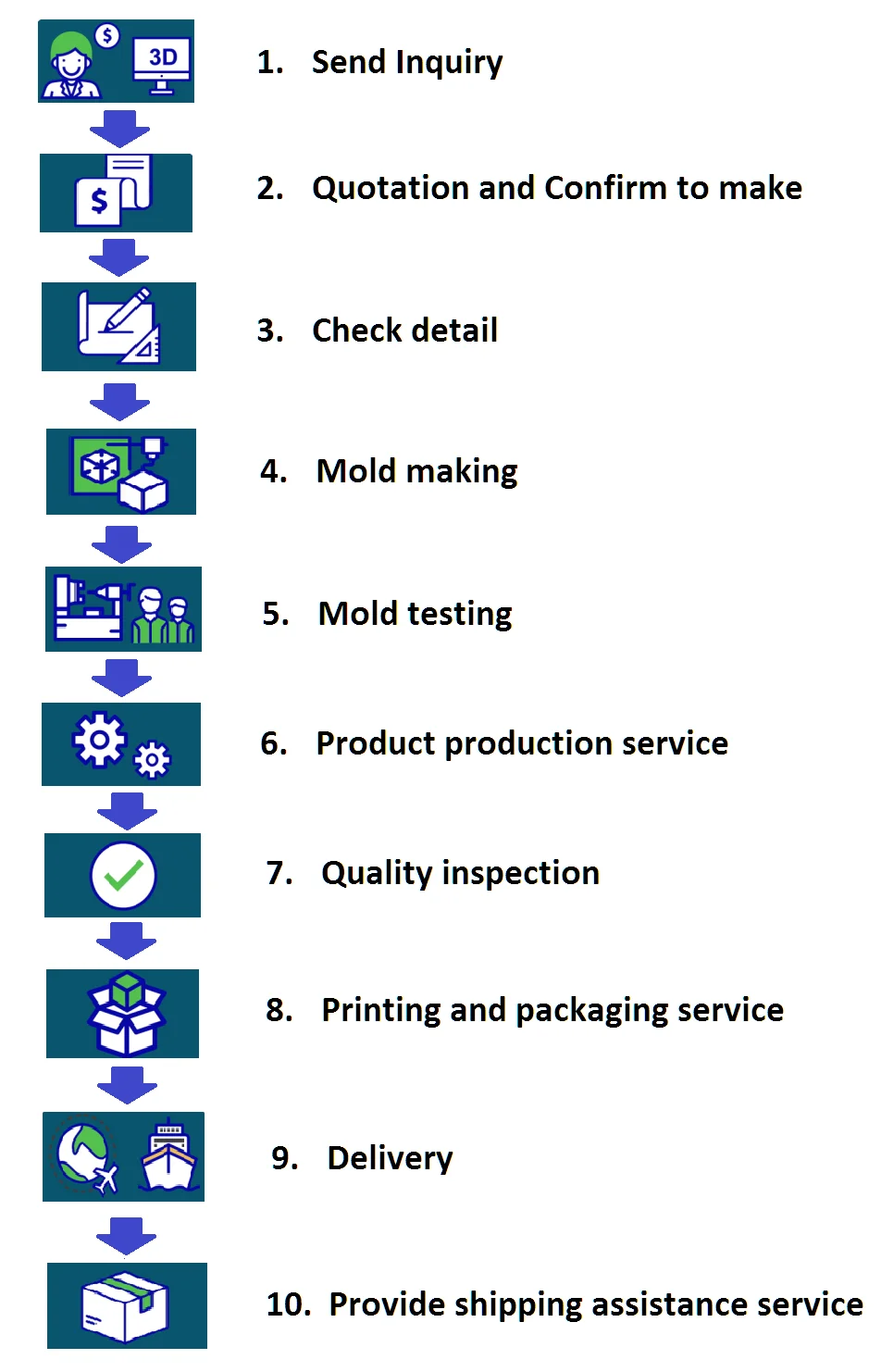

1. Send Inquiry

2. Quotation and Confirm to make

3. Check detail

4. Mold making

5. Mold testing

6. Product production service

7. Quality inspection

8. Printing and packaging service

9. Delivery

10. Provide shipping assistance service

Mold Making Machine Equipment

1. EDM 2. Lathing machine

3. Milling Machine 4. Grinding machine

5. Drilling Machine 6. Band saw

7. 3D Printer 8. CNC Lathing

Intertech makes good quality new custom mold and molded parts for any plastic, silicone and metal project, please send us your project now !

Sample order is available after our discussion !

We can give you some suggestion for our best selling mold and molding parts project working way !

May we have your Whatsapp number ? we can talk there more quickly or you

can add ours Whatsapp: +886.9328.66329

Material dealing: (included but not limited to, can be discussed)

- Liquid silicone rubber, general grade

(injection, misty color, for food grade product usage)

- Liquid silicone rubber, diving mask grade

(injection, transparent, for food grade product usage)

- Liquid silicone rubber, top grade

(injection, super transparent, for food grade product & medical products usage)

Visit us to know more! www.taiwanmoldmaker.com

Write to us with your ideas, projects... Email: intertech@seed.net.tw

Add our Facebook! Taiwan Mold Maker

Taiwantrade.com and iDealEZ.com uses analytical cookies and other tracking technologies to offer you the best possible user experience. By using our website, you acknowledge and agree to our cookie policy.

For more information on cookies or changing your cookies settings, read Taiwantrade & iDealEZ’s Privacy Policy.