Taiwan good quality baby nipple mold supplier

Intertech is a professional nipple, pacifier mold & baby nipple mold services Supplier. We provide LSR parts mold and molded parts for our customers. Find more services information here or contact us.

* 6 cavity high quality food grade liquid silicone rubber (LSR) baby nipple mold

* We make professional nipple mold which can produce with 100% food grade, soft, non-toxic, free of BPA silicone material, high temperature resistant and tear resistance, durable molding parts quality.

*Due to the liquid nature of the material, is easy to get flash. So, molds for LSR molding needs a super high precision mold making skill to complete this molding parts job with flashless or less goal.

Intertech is just such a professional and knowledgeable mould supplier in designing such LSR mold with the most optimized ejection and venting consideration to help our customer to build up their production line.

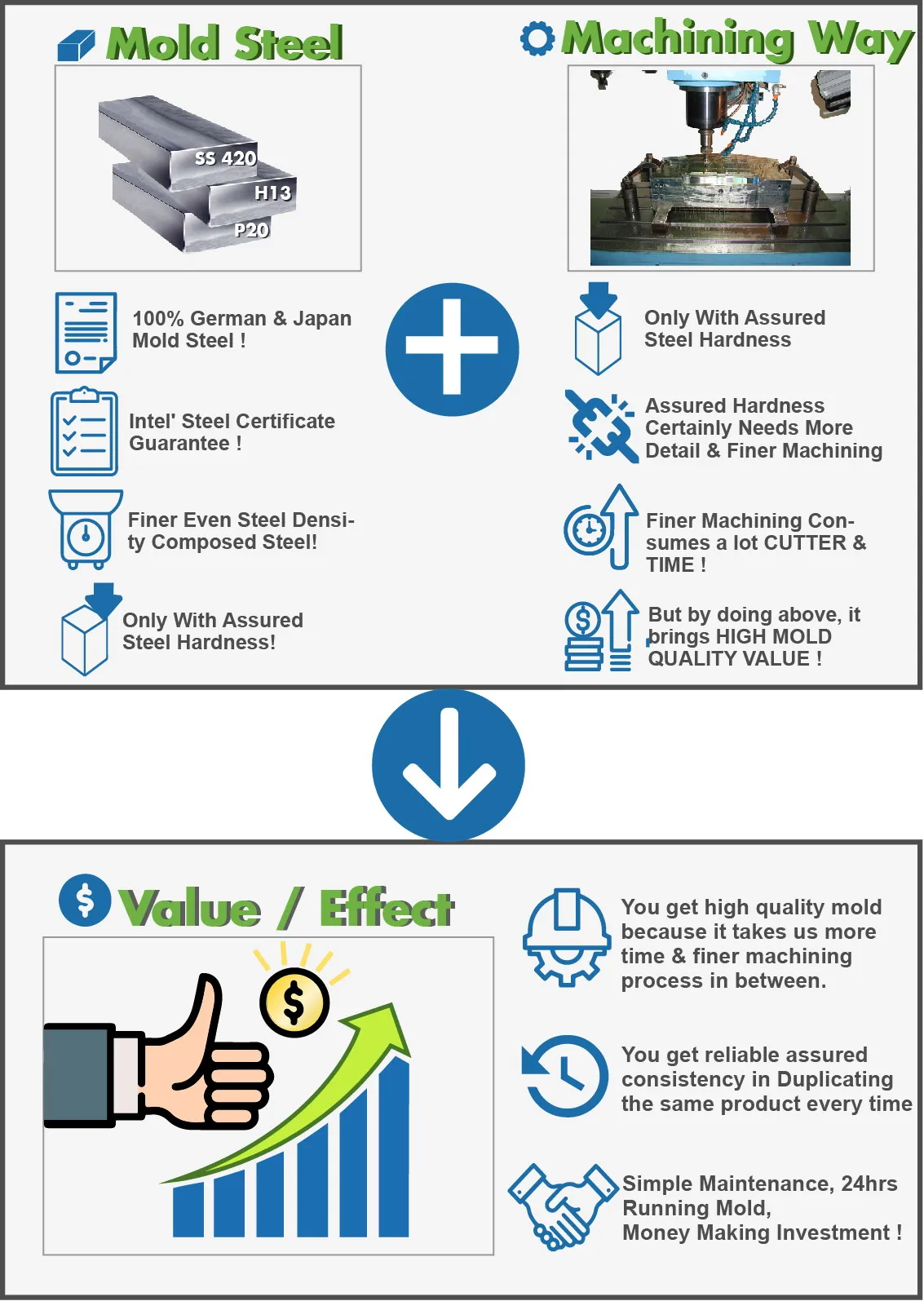

*The mold steel we use is 420 for food grade product to do the production which will not be rusty and very stable.

*For the LSR mold making and molding technology, we have much more experience in its application, and we can provide more solution than the other regular suppliers. Welcome to send us new LSR mold and molding project.

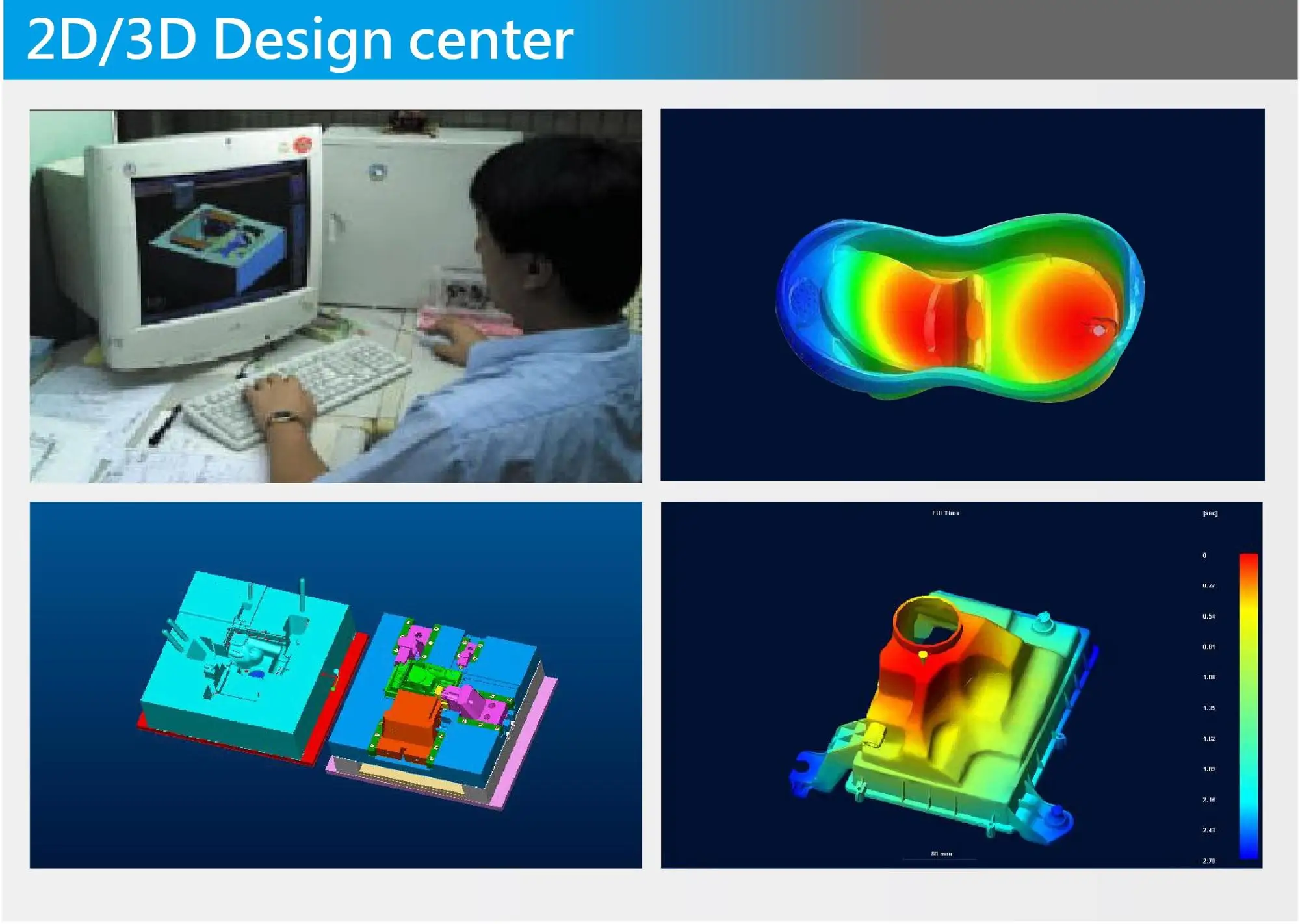

For mold design, …

- The software we use includesPro-Engineer, I-Deas, Cimetron, Auto-Cad & Solidworks.

- Cutomer can send 2D, 3D, by.igs .stp,formats to us.

- We can provide mold flow analysis service.

- Mold design (with the best optimized mold water channel arrangement design and the best cycle time performance consideration design)

In addition, CNC milled prototype, 3D printing prototype, prototype mold making service, fixture / jig making or welding horn design and making are

available in Intertech with good experience !

We need 2D, 3D parts design to start our job, we can sign NDA (if needed)

For mold making:

When making mold project, per customer’s requirement for mold steel material, we choose the suitable mold steel grade for our customers. We have high quality German and Japan imports mold steel material to proceed our mold project making. Then, the gating way will be discussed, the mold surface will be discussed, the mold cooling channel design will be checked, the operation style will be discussed, the molding machine size will be determined and the mold mechanism in actual production movement will all be checked as well. Only after our mold engineers discussing with our customers for the mold engineering in detail, we will proceed with our mold making job.

Contact us

Intertech makes good quality new custom mold and molded parts for any plastic, silicone and metal project, please send us your project now !

Sample order is available after our discussion !

We can give you some suggestion for our best selling mold and molding parts project working way !

May we have your Whatsapp number ? we can talk there more quickly or you

can add ours Whatsapp: +886.9328.66329

For Mold Inquiry, Customer Must prepare:

- Product drawing with 2D(.dwg)and 3D (.igs, .stp…etc)?

- Advise product material (ex. Plastic ,rubber, silicone rubber or metal…etc )?

- Molding machine tonnage size and platen size?

- The cavity number of the mold that you want us to quote?

- Mold steel grade that you want us to quote?

- Hot runner or cold runner mold required?

- Mold gating inlet preferred?

- Mold ejection way preferred?

- Other related information required …(ex. Polishing , texture, engraving …etc)

For Molding Products Inquiry , customer must prepare:

- Products material required? (ex. Plastics, rubber , silicone , metal…etc)

- Products quality required in total?

- Delivery time required?

- Post machining or not information? (ex. Chromed plate.., painting …etc)

- Assembly or not information?

- Packing or not information?