Intertech provides high precision blanking, piercing, bending, forming, washing, packing process service…etc.

Up to your project need, Intertech will customize the best die working stations either with few punch dies stamping way or progressive stamping die way

Intertech provides high precision blanking, piercing, bending, forming, washing, packing process&injection die , Die sets factory service …etc.

punch dies stamping way or progressive stamping die way.

- Post machining service is also provided per customer’s requirement.

Intertech is one of the leading company in odm die steel industry with its high quality and competitive price.

We provide odm die steel &injection die, Die sets factory.

Our goal is to provide customers products of high quality, competitive price, and superior services.

We are a professional punch die making factory with Hasco standad, European standar quality.

We are experienced in building the dies for stamping, bening & punching for forming metal parts in OEM & ODM projects.

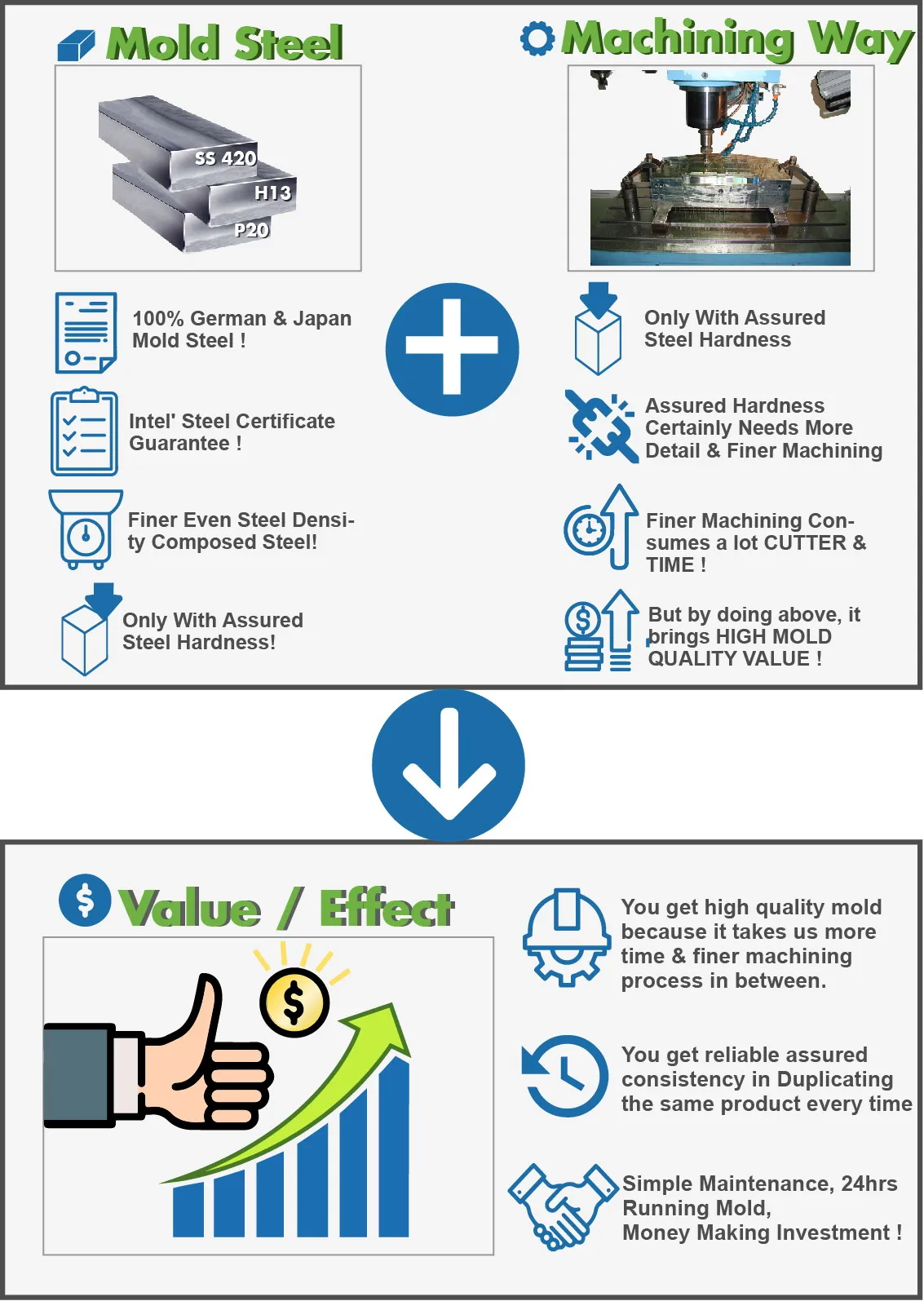

We use German and Japan imports steel to make our die sets, steel available wit

h Buderus, Assab, AISI & JIS, P20, H13, Starvax 420. - We are capable in dealing aluminum stamping die sets, sheet metal stamping die & stainless steel stamping die.

We provide cutomized molding, coating & assembly service as well.

We can also make a specialized tooling to cut or to shape material for custom-made projects need.

The press die we make can cover a wide range of products from simple metal parts to complex metal pieces.

Progressive pressing die and bending die is availabel per each project need.

In addition, CNC milled prototype, 3D printing prototype, prototype mold making service, fixture / jig making or welding horn design and making are available in Intertech with good experience !

We need 2D, 3D parts design to start our job, we can sign NDA (if needed)

When making mold project, per customer’s requirement for mold steel material, we choose the suitable mold steel grade for our customers. We have high quality German and Japan imports mold steel material to proceed our mold project making. Then, the gating way will be discussed, the mold surface will be discussed, the mold cooling channel design will be checked, the operation style will be discussed, the molding machine size will be determined and the mold mechanism in actual production movement will all be checked as well. Only after our mold engineers discussing with our customers for the mold engineering in detail, we will proceed with our mold making job.

Intertech makes good quality new custom mold and molded parts for any plastic, silicone and metal project, please send us your project now !

Sample order is available after our discussion !

We can give you some suggestion for our best selling mold and molding parts project working way !

May we have your Whatsapp number ? we can talk there more quickly or you

can add ours Whatsapp: +886.9328.66329

Are you from the EU regions?

Taiwantrade.com and iDealEZ.com uses analytical cookies and other tracking technologies to offer you the best possible user experience. By using our website, you acknowledge and agree to our cookie policy.

For more information on cookies or changing your cookies settings, read Taiwantrade & iDealEZ’s Privacy Policy.