intertech is a leading maker for automotive molds, car parts mold, auto parts mould and auto molds in Taiwan. Intertech's services include prototyping, tooling, lab testing, sampling, pilot run, mass production and assembly.

customer's concept of products will be brought out from design to the discussion to its completion through our designers and engineers.

The most basic parts of any car are the engine, fuel system, ignition system, battery, charging system, starting system, cooling system, transmission, steering system and timing belt. Modern cars also usually have on-board diagnostics, an emissions system, electrical systems and dashboard gauges.

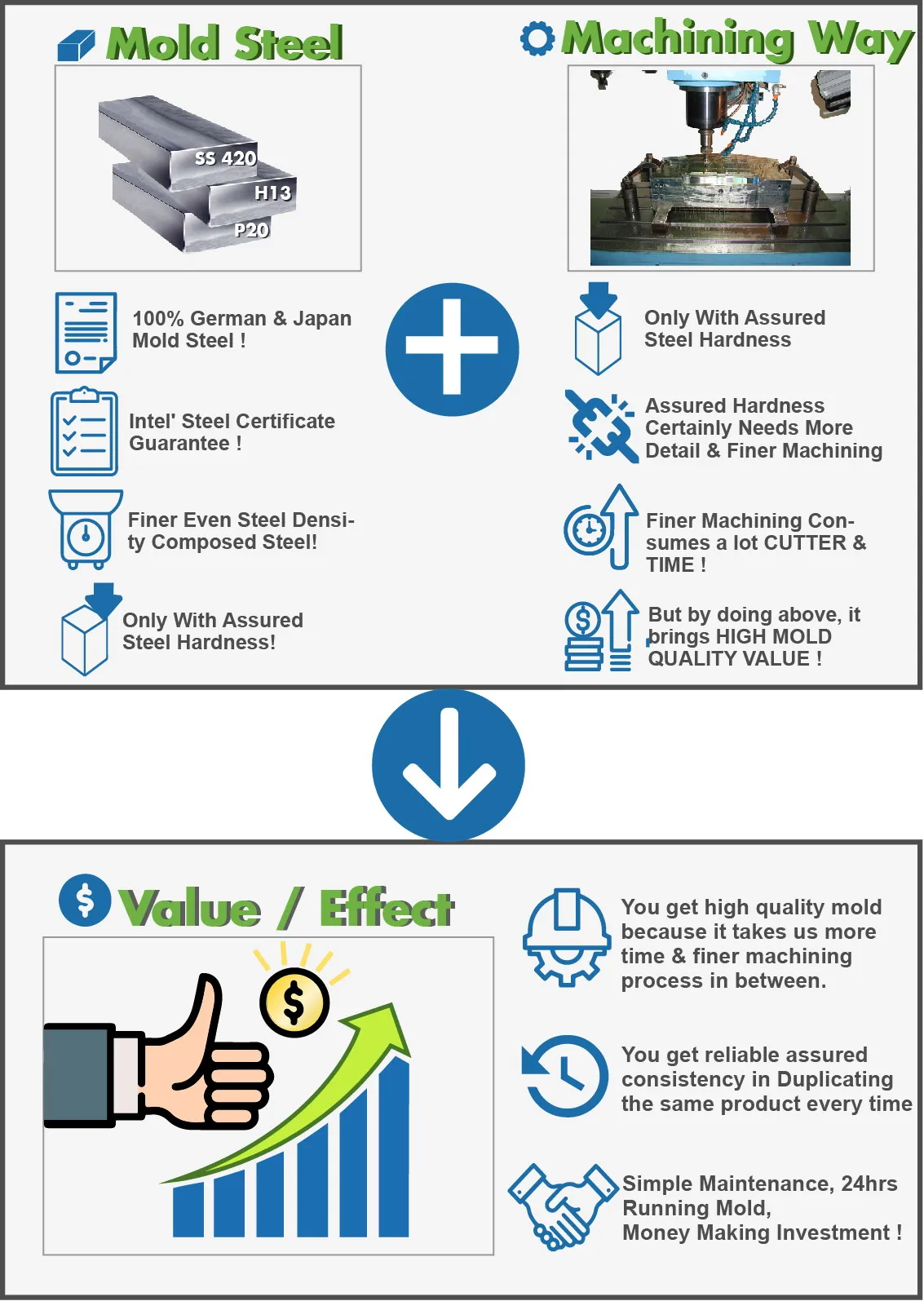

When making Automotive solutions & application project, per customer’s requirement for car parts mold steelmaterial, we choose the suitable mold steel grade for our customers.

Intertech makes good quality new custom mold and molded parts for any plastic, silicone and metal project, please send us your project now !

Sample order is available after our discussion !

We can give you some suggestion for our best selling mold and molding parts project working way !

May we have your Whatsapp number ? we can talk there more quickly or you

can add ours Whatsapp: +886.9328.66329

We provide low volume, pilot run of production job and mass production for customer.

Taiwantrade.com and iDealEZ.com uses analytical cookies and other tracking technologies to offer you the best possible user experience. By using our website, you acknowledge and agree to our cookie policy.

For more information on cookies or changing your cookies settings, read Taiwantrade & iDealEZ’s Privacy Policy.