Precision Punch Die Molded manufacturer:

1. OEM projects manufacture

2. Make both mold & part

3. Mold flow analysis available

Precision Punch Die Molded manufacturer

Intertech makes good quality new custom mold and molded parts for any plastic, silicone and metal project, please send us your project now !

Sample order is available after our discussion !

We can give you some suggestion for our best selling mold and molding parts project working way !

May we have your Whatsapp number ? we can talk there more quickly or you

can add ours Whatsapp: +886.9328.66329

1. Can supply with both Mold & Molded parts.

2. Provide Milled Prototype Making, Mold Design, Mold Making, Mold Testing, Molding, Products assembly...services.

3. With more than 25 years experience, all of works are done 100% in our factory in Taiwan!

4. Low volumes / Small orders are welcome! Please contact us to discuss case by case.

5. Accept only OEM / ODM / Customer Projects. We do not have any existing molds for sell.

6. Mold building lead time: Around 40-50 days, with 1st Mold trialing report and Mold trailing samples.

Product Highlight:

| Plastic materials: | PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PBT+GF30%...etc. |

| Other materials: | Rubber, Silicone rubber, LSR, aluminum, zinc...Metal...etc. |

| Quality: | ROSH and SGS standard |

| Feature: | Non marking and Non flash |

| Size: | According to your drawing |

| Color, Quantity, Unit price, Tooling cost, Tooling size: | To be discussed |

| Mold structure: | Injection Mould, Plastic Mold, Overmould, 2k mould, Die-Casting Mould, Thermoset Mold, Stack Mold, Interchangeable Mold, Collapsible Core Mold, Die Sets, Compression Mold, Cold runner system LSR Mold,…etc. |

| Mould Base: | HASCO standard, European standard, World standard |

| Mould Base Material: | LKM, FUTA, HASCO, DME, etc. or as per customer’s requirement. |

| Surface Finish: | Texture (MT standard), high gloss polishing |

| Finish: | Mirror finish etc. |

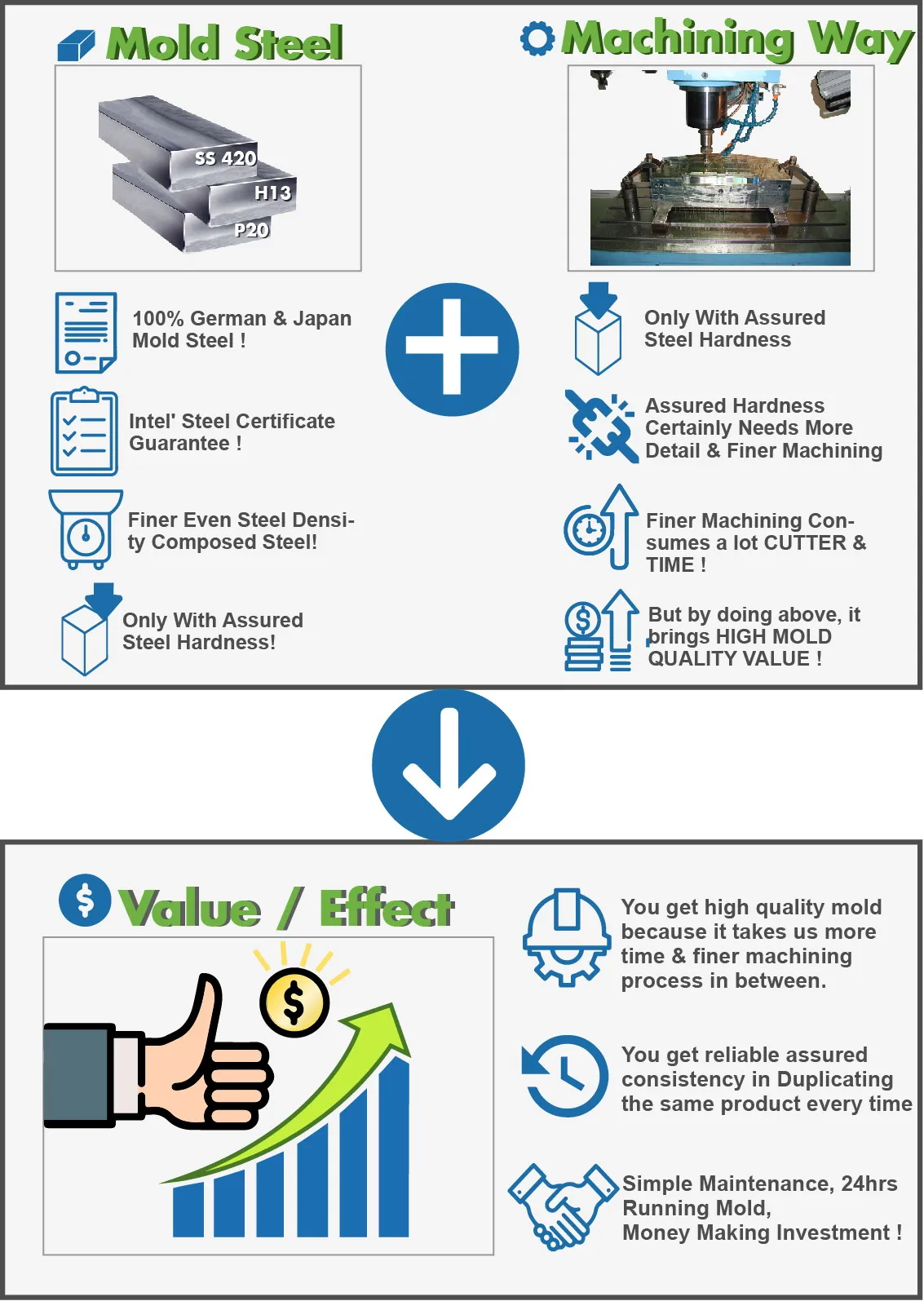

| Cavity / Core steel: | P20, 2311, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 etc. |

| Cavity: | Single cavity, Muti Cavity, based on customer’s requirement. |

| Hot / Cold Runner: | HUSKY, INCOE, YUDO, HASCO, DME, MoldMaster, Masterflow, Mastip, Taiwan made brand…etc. |

| Mould Life: | 1,000 to 1,000,000 shots (according to your working environment) |

| Design & Program Softwares: | CAD, CAM, CAE, Pro-E, Solid works…etc. |

| Equipments: | High speed CNC, standard CNC, EDM, Wire Cutting, Grinder, Plastic Injection Molding Machine for testing mold from 50-3000T available. |

| Package: | Standard exported wooden box packed, fumigation process (upon required) |

| Mold building lead time: | T1, 20~50 days, parts measurement report (upon required). |

| Annual production: | 250 sets of mold |

In short, We can provide you both products and molds in best quality.

All of our products and molds are 100% designed and made here, in Taiwan.

We are confident to satisfy our customers with best value of moldmaking workmanship.

Are you from the EU regions?

Taiwantrade.com and iDealEZ.com uses analytical cookies and other tracking technologies to offer you the best possible user experience. By using our website, you acknowledge and agree to our cookie policy.

For more information on cookies or changing your cookies settings, read Taiwantrade & iDealEZ’s Privacy Policy.