Silicone Nipple Mold

Intertech is a professional nipple, pacifier mold & baby nipple mold services Supplier. Find more nipple mold, pacifier mold & baby nipple mold services information here or contact us for full service.

Intertech is a professional mam pacifier mold,custom silicone baby pacifier mold, baby pacifiers mold & mam soothers mold ,liquid silicone pacifier,transparent liquid silicone rubberservices Supplier. Find more mam pacifier mold, baby pacifiers & mam soothers mold services information here or contact us for full service.

* 4 cavity high transparent liquid silicone rubber (LSR) baby pacifier mold

* Due to the liquid nature of the material, LSR mold is easy to get flash. So, molds for LSR molding needs a super high precision mold making mould skill to complete this molding parts job with flashless or less goal. Intertech is just such a professional and knowledgeable mold maker in designing such LSR mold with the most optimized injection and venting consideration to help our customer to build up their production line.

*The mold steel we use is 420 for food grade product to do the production which will not be rusty and very stable. Transparent liquid silicone pacifier.

*For the LSR mold making and molding technology, we have much more experience in its application, and we can provide more solution than the other regular suppliers.

Welcome to send us new LSR mold and molding project.

Intertech has abundant experience in manufacturing liquid silicone pacifier since its establishment in 1987. We provide liquid silicone pacifier & transparent liquid silicone rubber. We are a customer-focused company, hence we take our customer’s requirements very seriously.

| Plastic materials: | PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PBT+GF30%...etc. |

| Other materials: | Rubber, Silicone rubber, LSR, aluminum, zinc...Metal...etc. |

| Quality: | ROSH and SGS standard |

| Feature: | Non marking and Non flash |

| Size: | According to your drawing |

| Color, Quantity, Unit price, Tooling cost, Tooling size: | To be discussed |

| Mold structure: | Injection Mould, Plastic Mold, Overmould, 2k mould, Die-Casting Mould, Thermoset Mold, Stack Mold, Interchangeable Mold, Collapsible Core Mold, Die Sets, Compression Mold, Cold runner system LSR Mold,…etc. |

| Mould Base: | HASCO standard, European standard, World standard |

| Mould Base Material: | LKM, FUTA, HASCO, DME, etc. or as per customer’s requirement. |

| Surface Finish: | Texture (MT standard), high gloss polishing |

| Finish: | Mirror finish etc. |

| Cavity / Core steel: | P20, 2311, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 etc. |

| Cavity: | Single cavity, Muti Cavity, based on customer’s requirement. |

| Hot / Cold Runner: | HUSKY, INCOE, YUDO, HASCO, DME, MoldMaster, Masterflow, Mastip, Taiwan made brand…etc. |

| Mould Life: | 1,000 to 1,000,000 shots (according to your working environment) |

| Design & Program Softwares: | CAD, CAM, CAE, Pro-E, Solid works…etc. |

| Equipments: | High speed CNC, standard CNC, EDM, Wire Cutting, Grinder, Plastic Injection Molding Machine for testing mold from 50-3000T available. |

| Package: | Standard exported wooden box packed, fumigation process (upon required) |

| Mold building lead time: | T1, 40~50 days, parts measurement report (upon required). |

| Annual production: | 250 sets of mold |

About Us:

In short, Intertech (Taiwan) provides an extensie integrated operational ability from design to production of molds 100% made in Taiwan.

With the performance level in Taiwan, we satisfy our world customers with the best value of mold making workmanship: customer design service; prototyping; mold making;manufacturing process control; reverse engineering; customer molding & assembly...etc.

We manufacture plastic injection molds, die-casting molds, silicone rubber molds, liquid silicone rubber molds, LSR molds, rubber molds, press molds and hot runner molds (MoldMaster, MasterFlow, LKM, Incoe systems...etc).

We are particularly specialized in dealing with undercut molds, unscrewing molds, core pulling structure molds, high gloss polished molds, interchangeable core molds, hot compression molds, 2-component injection molds, and pilot molds for small series production...etc.

Supplier Advantages

Minimizing waste & Energy Saving & Recylable

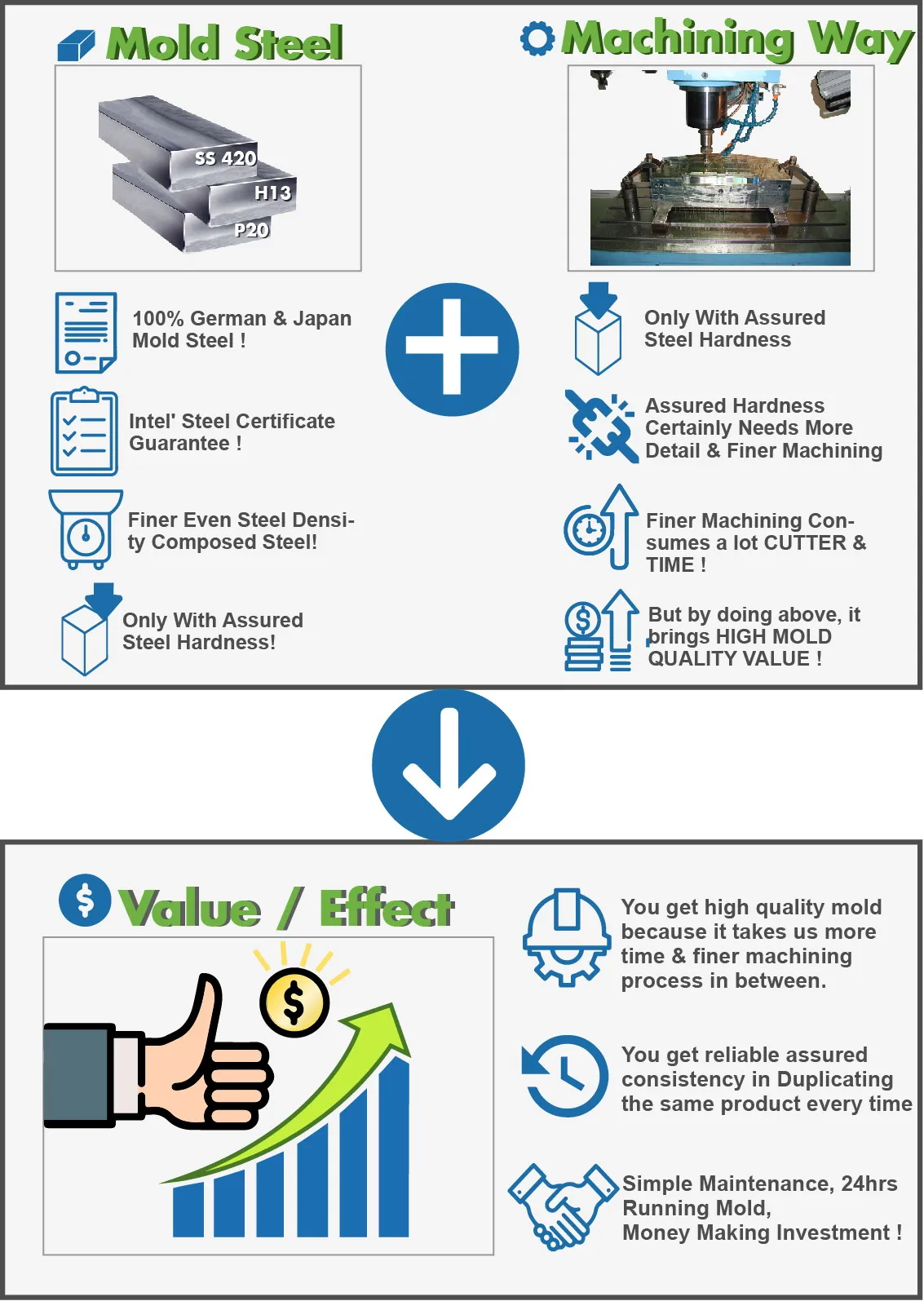

Mold Steel Advantage Finer Machining Way Benefit

100% German & Japan Mold Steel ! Only With Assured Steel Hardness

Intel' Steel Certificate Guarantee ! Assured Hardness Certainly Needs

Finer Even Steel Density Composed Steel! More Detailed & Finer Machining !

Only With Assured Steel Hardness! Finer Machining Consumes a lot CUTTER&TIME

But by doing above, it brings HIGH MOLD

QUALITY VALUE ! !

High Mold Quality Value

You get high quality mold because it takes us more time & finer machining process in between.

You get reliable assured consistency in

Duplicating the same product every time !

Simple Maintenance, 24hrs Running Mold, Money Making Investment !