Medical | ||||

Car | ||||

Fittings | ||||

Led |

Mold Steel Advantage Finer Machining Way Benefit

100% German & Japan Mold Steel ! Only With Assured Steel Hardness

Intel' Steel Certificate Guarantee ! Assured Hardness Certainly Needs

Finer Even Steel Density Composed Steel! More Detailed & Finer Machining !

Only With Assured Steel Hardness! Finer Machining Consumes a lot CUTTER&TIME

But by doing above, it brings HIGH MOLD

QUALITY VALUE ! !

High Mold Quality Value

You get high quality mold because it takes us more time & finer machining process in between.

You get reliable assured consistency in

Duplicating the same product every time !

Simple Maintenance, 24hrs Running Mold, Money Making Investment !

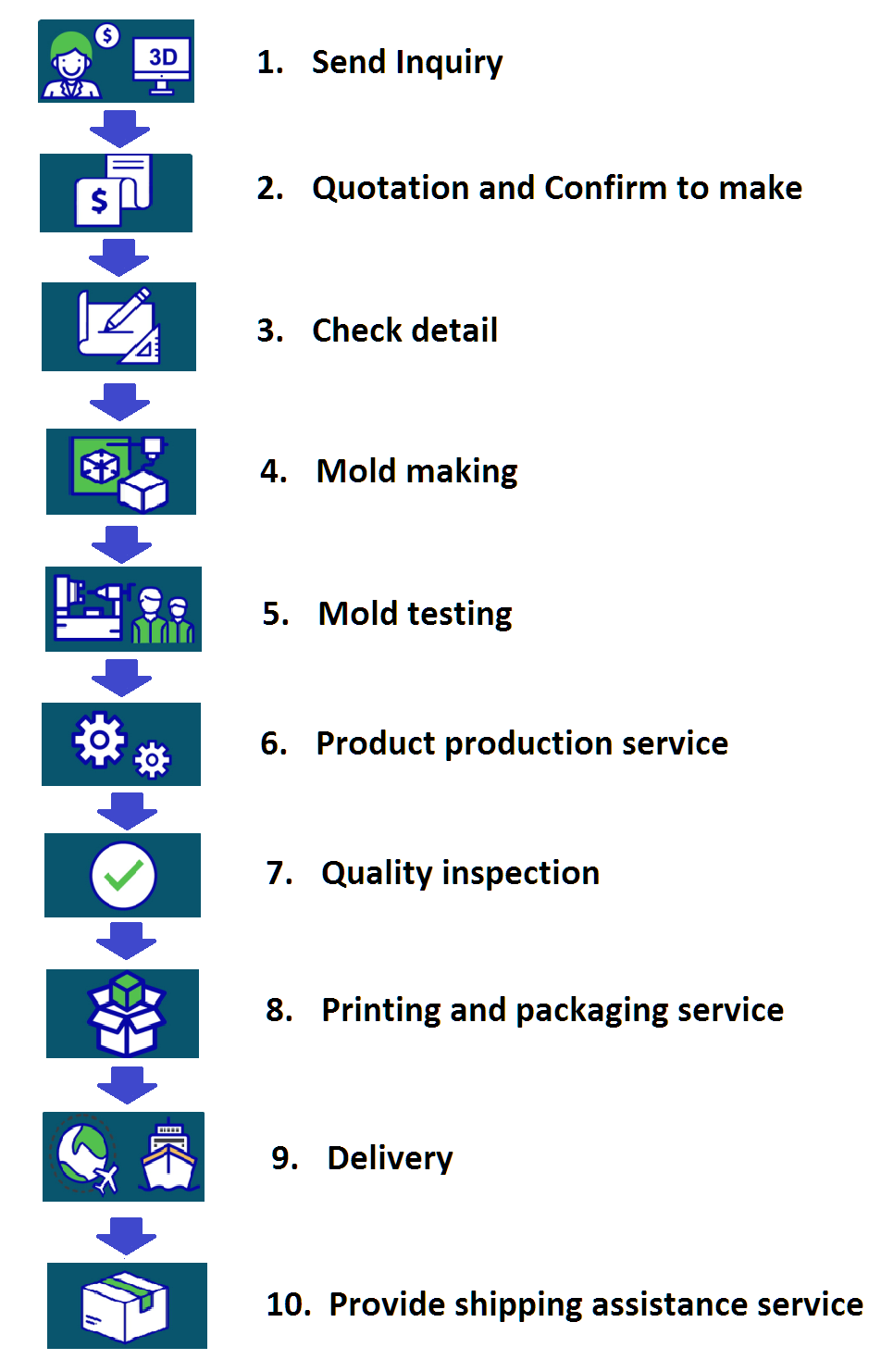

When making mold project, per customer’s requirement for mold steel material, we choose the suitable mold steel grade for our customers. We have high quality German and Japan imports mold steel material to proceed our mold project making. Then, the gating way will be discussed, the mold surface will be discussed, the mold cooling channel design will be checked, the operation style will be discussed, the molding machine size will be determined and the mold mechanism in actual production movement will all be checked as well. Only after our mold engineers discussing with our customers for the mold engineering in detail, we will proceed with our mold making job.

Taiwantrade.com and iDealEZ.com uses analytical cookies and other tracking technologies to offer you the best possible user experience. By using our website, you acknowledge and agree to our cookie policy.

For more information on cookies or changing your cookies settings, read Taiwantrade & iDealEZ’s Privacy Policy.